Sludge bed / Weeping wall

Effluent solids often cause problems with disposal systems. Separating solids makes effluent easier to manage and can result in cost savings.

The benefits of separating solids prior to effluent storage/land application are:

- Less frequent pond cleaning.

- Lower pumping costs.

- Better irrigator performance.

- Fewer blockages in sprinklers.

- Effluent solids can be stored until soil conditions are suitable.

- Gravel traps (which require frequent routine cleaning) are not needed.

- Saves both time and money.

How do sludge bed/weeping walls work?

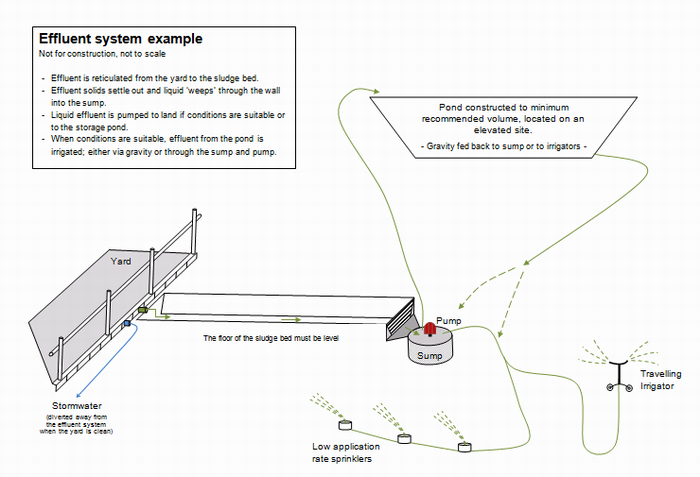

The system consists of a sludge bed to hold the effluent solids. Liquid effluent passes through a slatted wall at the end or side of the bed to a sump or pond.

For sludge bed/weeping wall systems to work well, they need:

- The floor of the sludge bed to be level or slightly sloping away from the wall.

- Long narrow sludge bed design.

- Enough volume to retain all solid effluent for at least six months.

- Enough drainage (and freeboard) to ensure all liquid effluent and rainfall generated in a 24 hour period is able to drain over those 24 hours.

- The effluent inflow is above the full sludge level of the bed and at (or nearly at) the opposite end to the wall.

- Access for solids to be removed by an excavator or front-end loader.

- The drainage (liquid outflow) to fall away from/below the bottom of the wall.

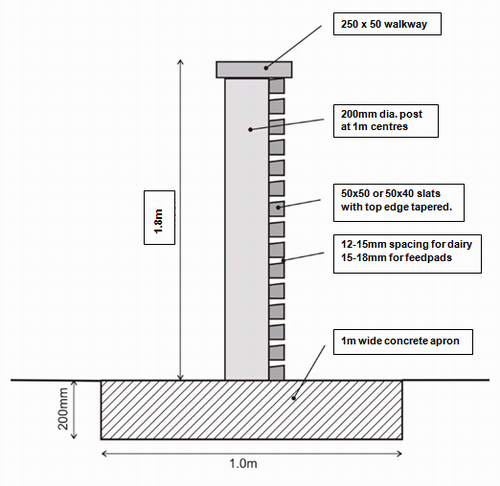

- Smooth slats on the wall with a tapered top edge – the narrow gaps should be on the sludge bed side of the wall (see schematic below).

Sludge beds

Each sludge bed should have a minimum of 30m3 of volume for every 100 cows (more volume is required if effluent from a feed or stand-off pad is to be treated). The sludge bed is 1-2m deep and has an internal batter of two to one (2:1). The floor of the sludge bed must be level (or slightly sloping away from the wall) to work effectively.

The weeping wall

The wall is constructed by installing posts at 1m centres and fastening 50mm x 50mm wooden slats (or plastic panels) to the posts. The top side of each slat is tapered to allow efficient liquid flow through the wall (see schematic below).

Design

Correct design and installation is critical. The required wall area is a minimum 5m2 (for more than 500 cows, add 1m2/100 cows).

The recommended gap between slats for effluent from:

- The dairy: 12-15mm

- A feed pad: 15-18mm

It is recommended that the slats are fixed to the posts when they are saturated as dry slats expand when they are wet and will close the gap.

The bottom of the wall (and concrete apron) must be above the level of the liquid in the channel/sump/pond to allow the sludge to dry.

Weeping wall schematic:

Weeping wall maintenance

Some maintenance is necessary to ensure ongoing effectiveness. This should include:

- Cleaning of the sludge bed at least once annually (the solids can be spread onto pasture or crop paddocks).

- Pressure washing of the wall/s while the sludge bed is empty (vital for the wall to be effective over time).

- Repair of any broken slats or knot holes after the wall has been cleaned.

Open a larger version of the effluent system example (below) in PDF format (23KB)

Accurate design and construction of a weeping wall is vital for it to work effectively.

If you are considering the installation of a weeping wall, please contact council's Farm Dairy Effluent Team for further information.

P: 0800 002 004